Select your Product

RoboCAP-RL Cartridge Filling Machine

Output Per Hour 1,200 - 2,000

Designed to optimize low-volume product filling (up to 5ml) for maximum efficiency, our RoboCAP RL-200 and RL-300 Volumetric (VF) utilizes backpressure, heat and volumetric displacement to guarantee a +/- 2% filling accuracy with the same speed and consistency as our other RoboCAP systemsClients can upgrade to 2 nozzles with our heating and mixing system and 4 nozzles without heating to meet every company’s production demands!

RoboCAP-RL Cartridge Filling Machine Specifications

Specification

RL-300

RL-200

Fill Rate (Per Hour)*

1,200 - 2,000

1,200 - 2,000

Weight (kg)

30

23

Height (mm)

590

472

Depth (mm)

500

584

Power Supply

AC 110 - 220V 300W

AC 100 - 230V 200W

Dispense Accuracy

+/- 2.5%

+/- 2.5%

Dispensable Volume Range

0.1ml- 5ml

0.1ml- 5ml

Temperature Range

0C - 100C

0C - 100C

Filling Capabilities

Cartridges, Capsules, Bottles, Tinctures, Balms, Creams

Cartridges, Capsules

*Based on 0.5g cartridge

RoboCAP-RL Cartridge Filling Machine Components

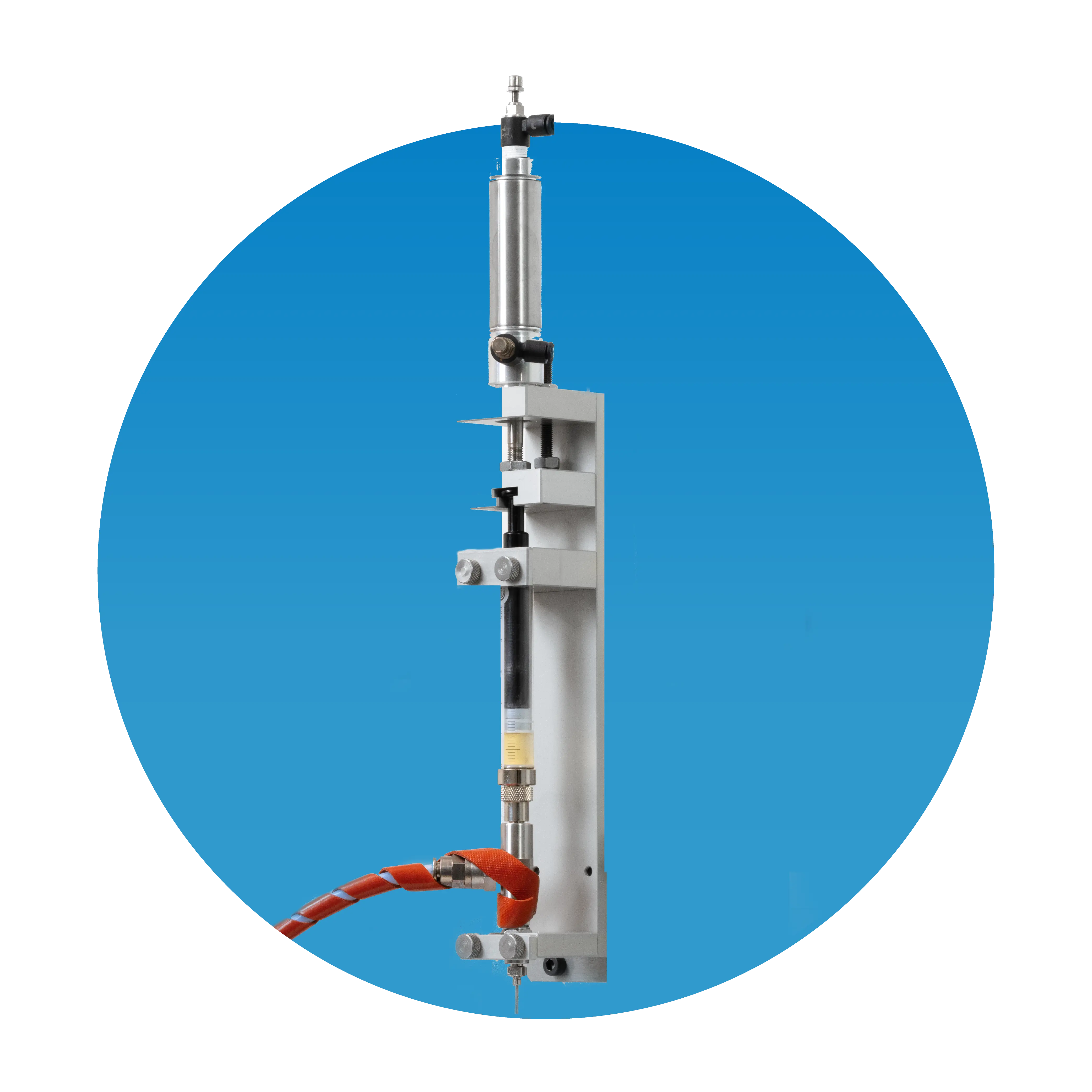

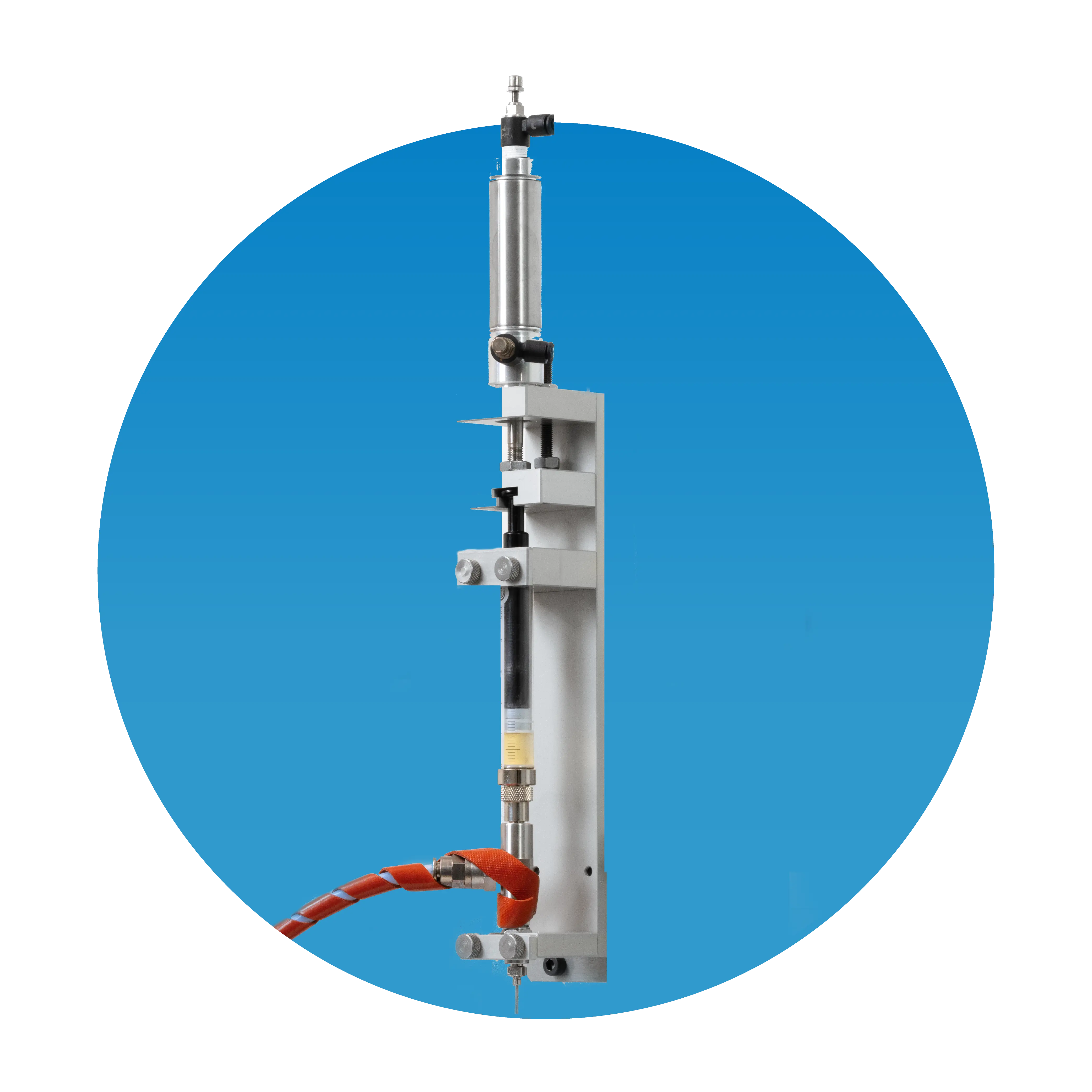

Dual Actuated VF+ Dispensing Nozzle

The VF+ dispensing nozzle takes control and consistency to the next level. Offering the ultimate solution for handling a variety of thicker oils with ease and less heat required (live resin/rosin, liquid diamond, RSO, etc.).Draw and dispense 50% faster per shot while achieving an incredible 2.5% precision rating. With an ability to fill up to 2ml of product, fill exactly what you need, with minimal waste.

Visit our suppliers:

RoboCAP VF+ Nozzle in action

Pressure Vessel

The bottom-out pressure vessels are designed with back pressure to guarantee all product flows evenly and consistently through the tubing. This ensures every bit of product is not wasted and reduces the chance of air bubbles in your product.The stainless-steel tanks range from 1L, 1g, 3g, 5g, and 10-gallon in size. All our pressure vessels are compatible with our mixers and heating systems for even heat distribution throughout the tank and cleaner filling process.

Visit our suppliers:

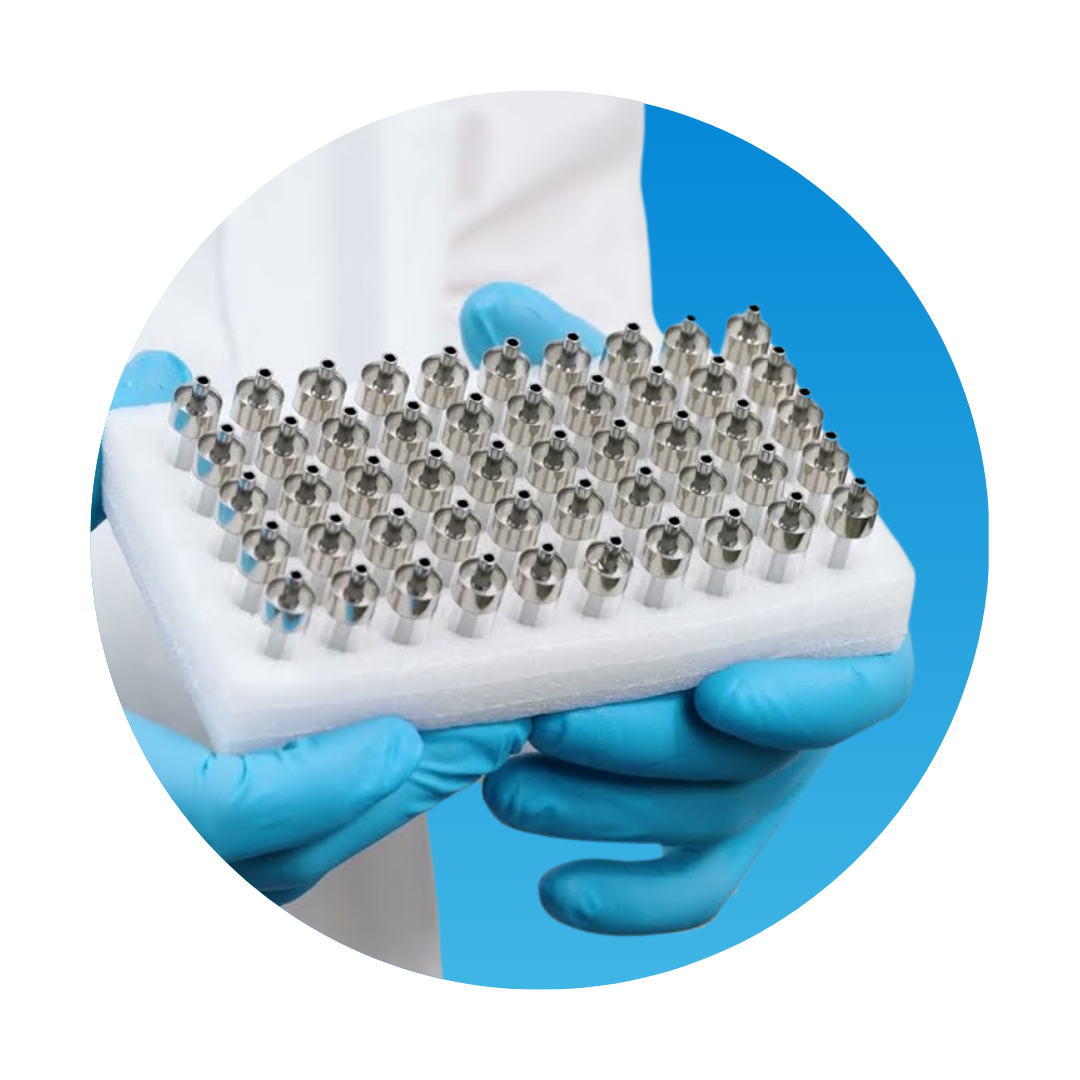

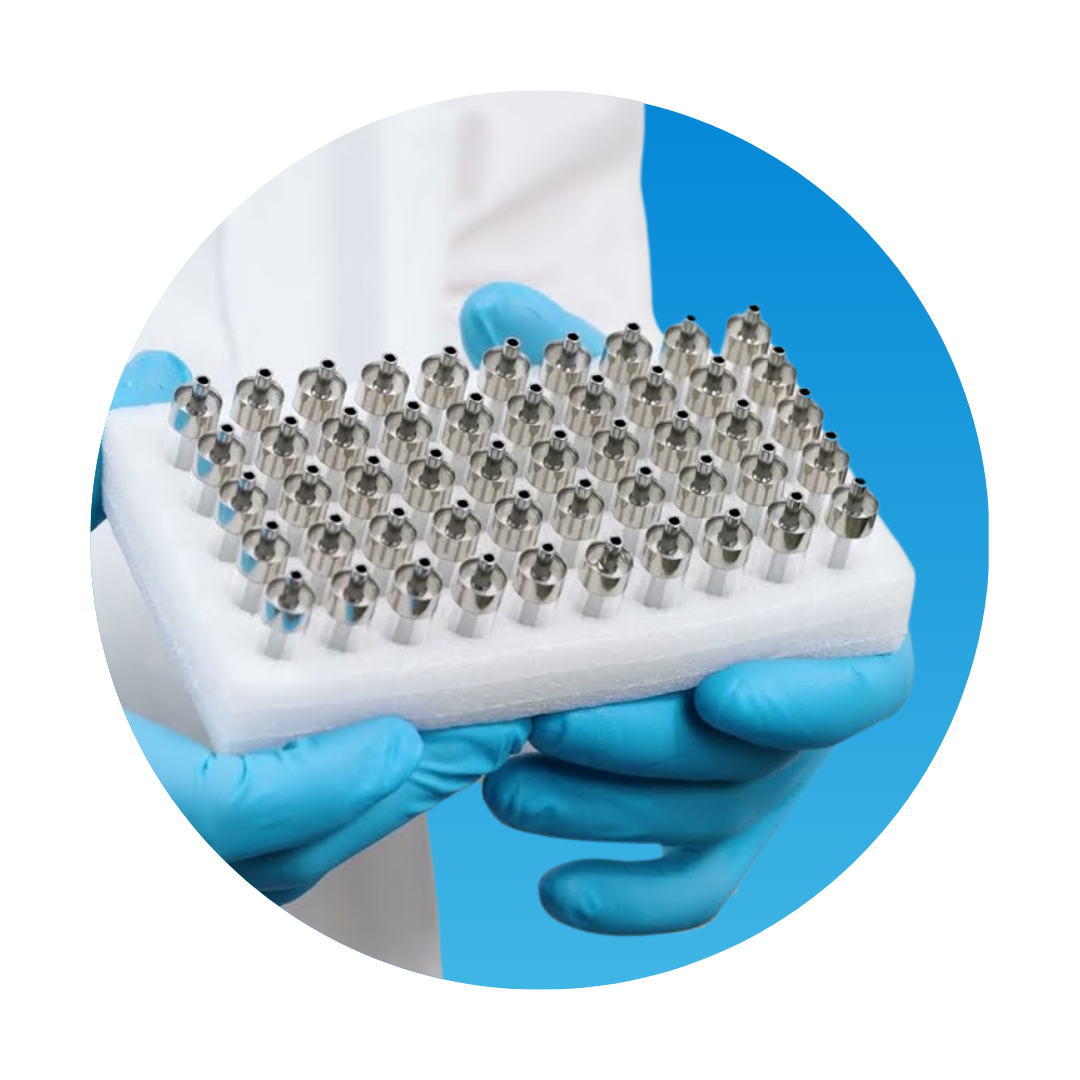

Pre-Loaded Trays

Experience the convenience of pre-assembled, plug-and-play trays, eliminating labour-intensive setup procedures.With preloaded foam trays, you can get up to a 4X increase filling and capping output with a potential savings of between $0.20 to $0.60 cents per unit in reduced labor and overhead costs. Preloaded trays come in default 50 blocks and can be fully customized for blocks of 100, 25, or any size your automation system requires. Fuly compatible with ATG filling machines.

Visit our suppliers:

We Work Hand-in-Hand with The World’s Top Brands

We have forged strategic partnerships with industry-leading vape hardware manufacturers to deliver cost-effective and time-efficient solutions for your needs.

Cartridge Filling in Action

Designed to optimize low-volume product filling, the VF nozzle dispenses product with a +/- 2% filling accuracy. Set the exact product volume you want and start filling!

Visit our suppliers:

Complete Your Production

MonoPress

Cartridge Press

The MonoBlox Product Suite consists of the MonoBlox, the MonoPress, and the MonoTray. This setup is ideal for filling & capping press top cartridges. The MonoBlox are custom cut for your cartridge sizes and are removable from the MonoTray so that the closing process can begin while the machine continues to fill. This eliminates any chance of leaking, clogging or oxidization.The system derives off of air pressure and is the perfect addition to your cartridge production line.

MonoPressin Action

The MonoBlox Product Suite consists of the MonoBlox, the MonoPress, and the MonoTray. This setup is ideal for filling & capping press top cartridges. The MonoBlox are custom cut for your cartridge sizes and are removable from the MonoTray so that the closing process can begin while the machine continues to fill. This eliminates any chance of leaking, clogging or oxidization.